Why MAHLE Teams Choose Poka to Accelerate Industry 4.0

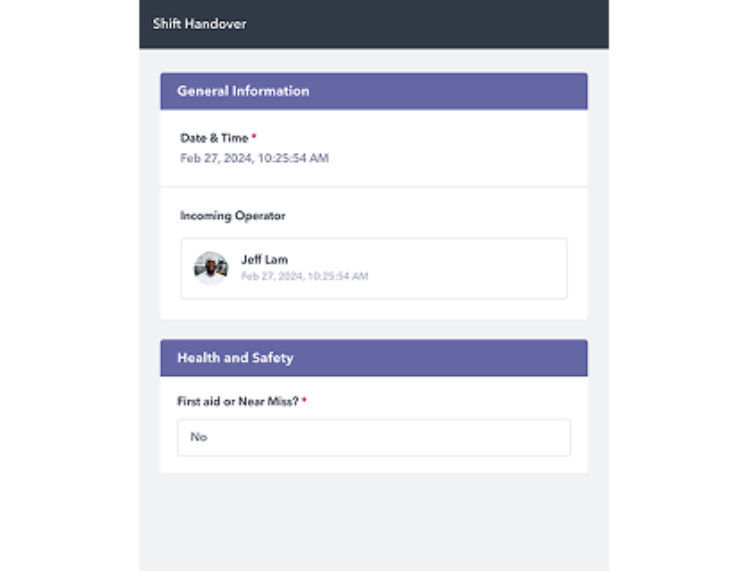

- Capture and share best practices with real-time visibility

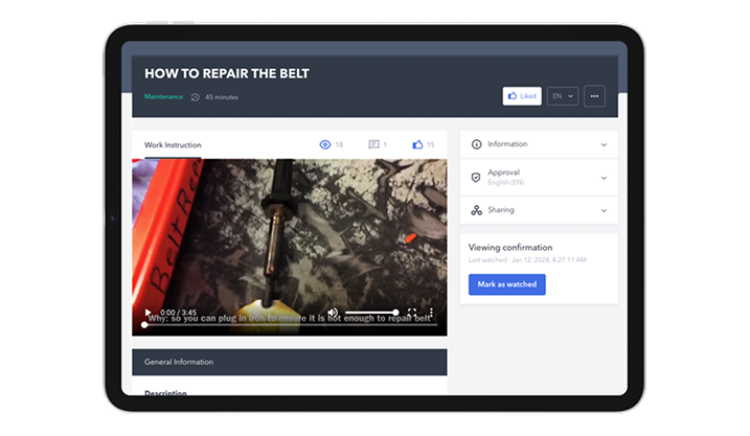

- Digital work instructions accessible anywhere

- Reduce downtime by connecting teams with digital troubleshooting tools

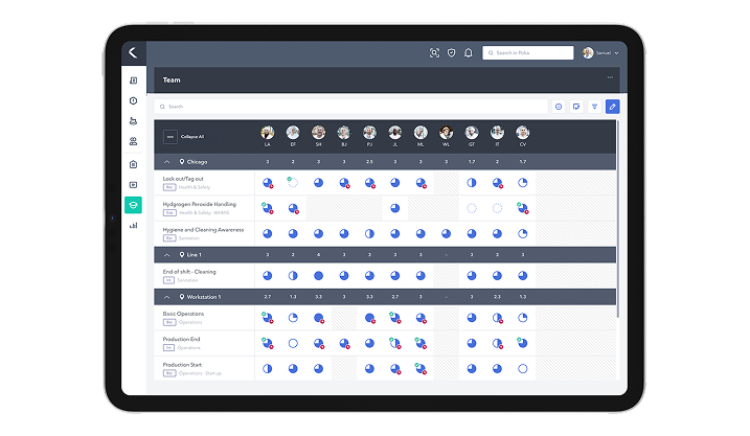

- Empower operators with multilingual access to SOPs and skill matrices

- Shorten onboarding and upskilling by up to 57%