CONTINUOUS IMPROVEMENT Empower a culture of Continuous Improvement (CI) by capturing, tracking, correcting and measuring incremental improvements, all in a single platform

Empower a culture of Continuous Improvement (CI) by capturing, tracking, correcting and measuring incremental improvements, all in a single platform

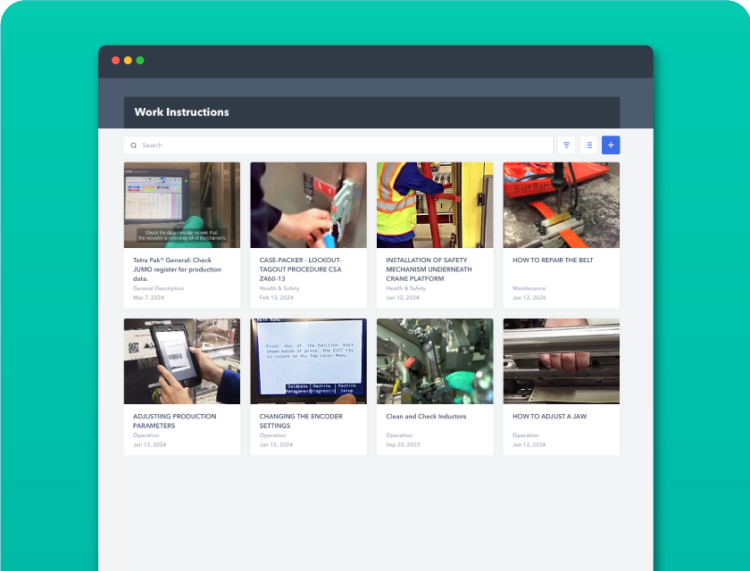

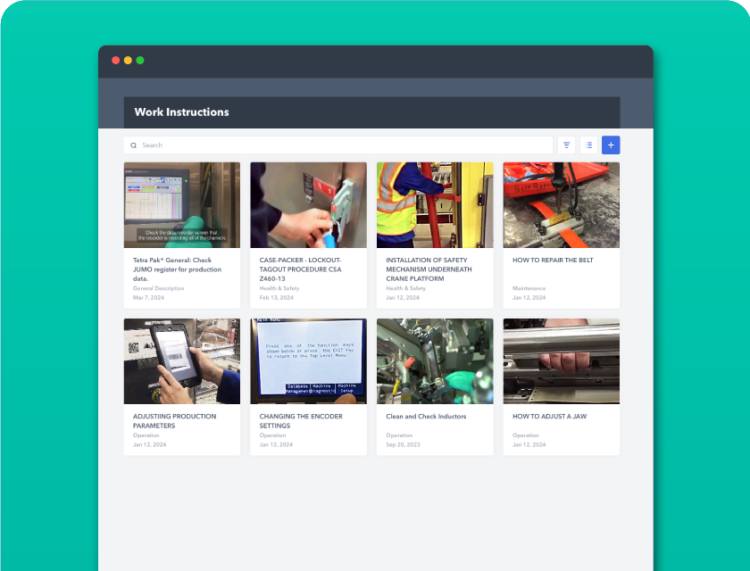

Improve access to CI-related content

Streamline CI training and certifications

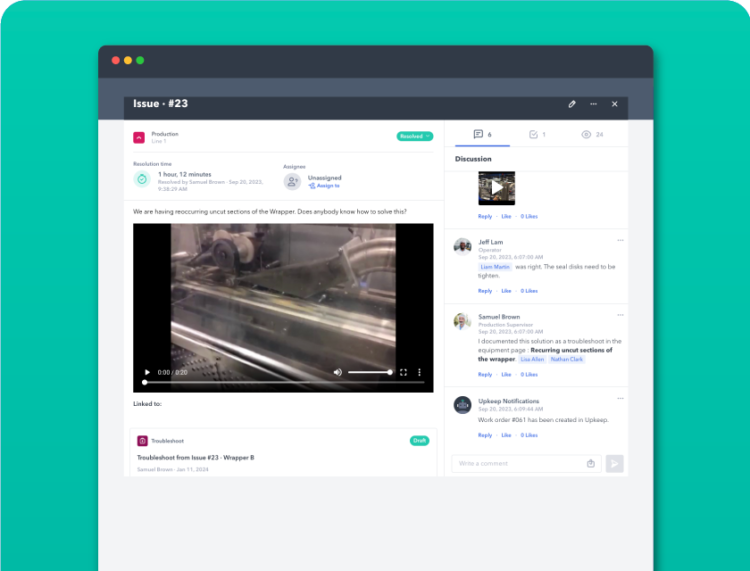

Empower collaboration for optimal team performance

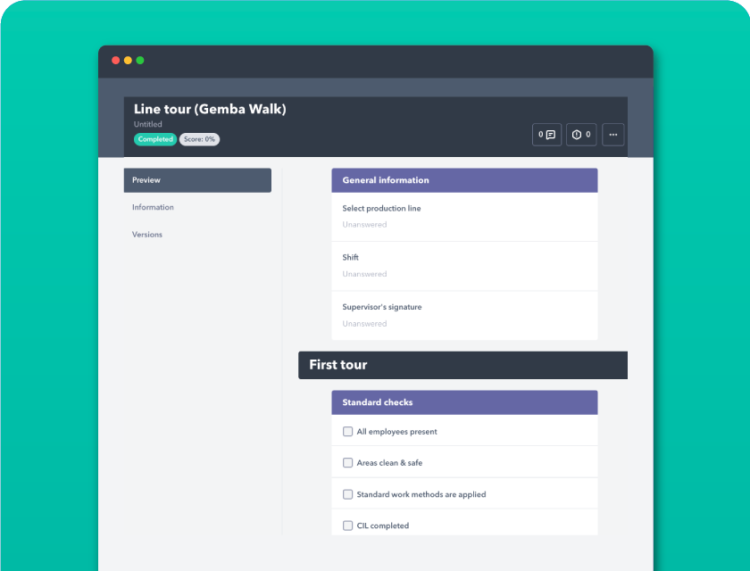

Ensure CI standards are followed

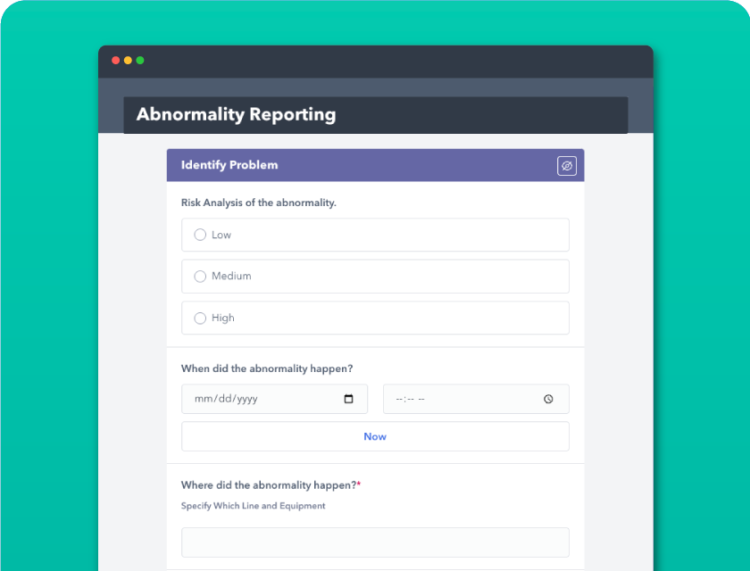

Identify and resolve issues faster

Capture, analyze and gain insight from CI data to spot opportunities for improvement

Streamline the creation, access and communication of CI related content with AI