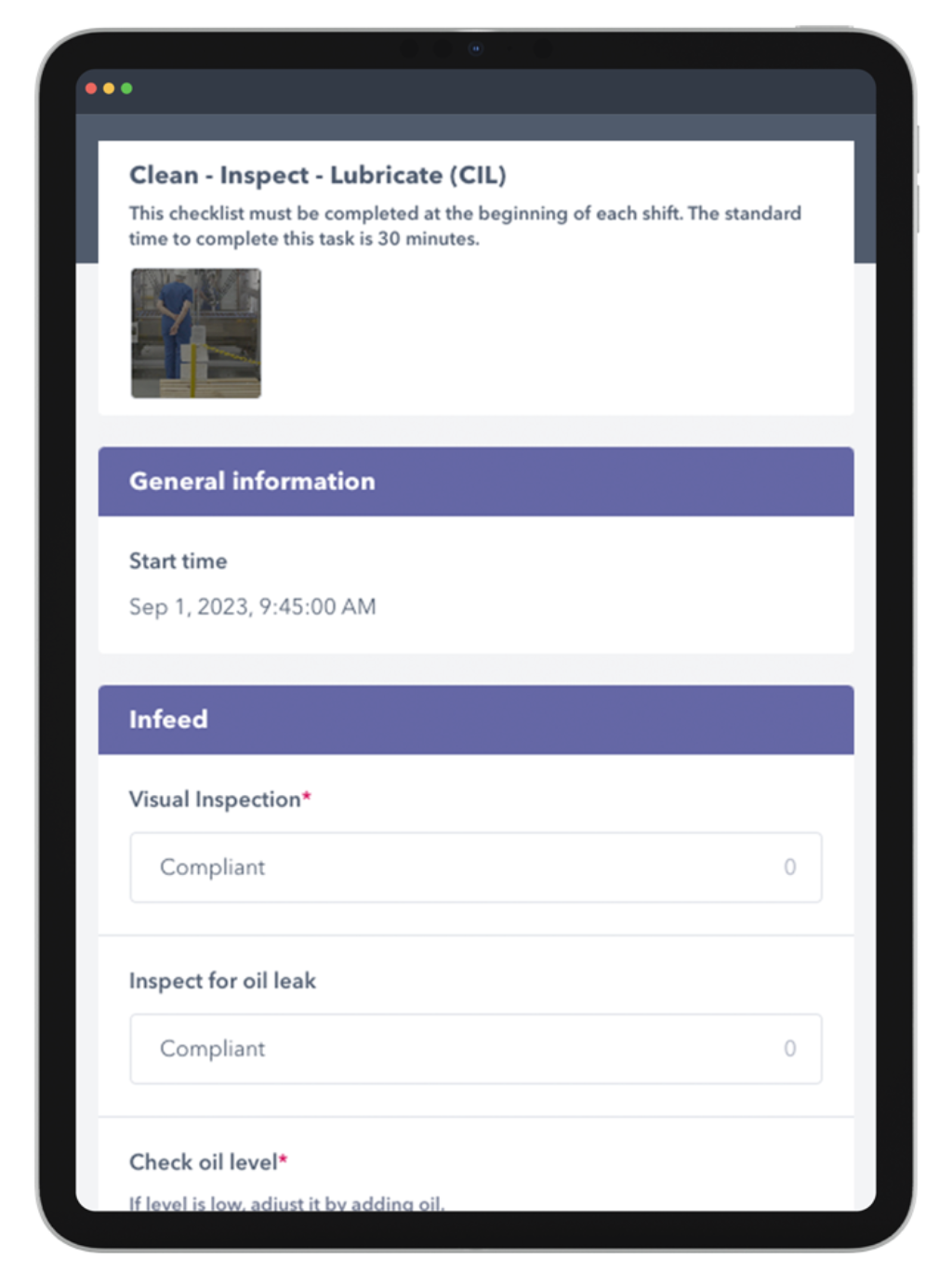

Forms & Checklists

Enhance content creation utilizing input from experienced operators to continually improve work instructions

Use mobile devices to capture real-world procedures and best practices from experienced operators

Enhance content creation utilizing input from experienced operators to continually improve work instructions

Use mobile devices to capture real-world procedures and best practices from experienced operators

Tacit knowledge refers to the experience, know-how, tips, tricks, and intuitive insights that experienced operators hold in their minds—often never documented. Capturing it digitally means converting that “in your head” knowledge into accessible, shareable content. In manufacturing, this is critical because when skilled workers retire, leave, or rotate, you risk losing essential process details. With digital capture, you preserve best practices, reduce risk, and sustain productivity.

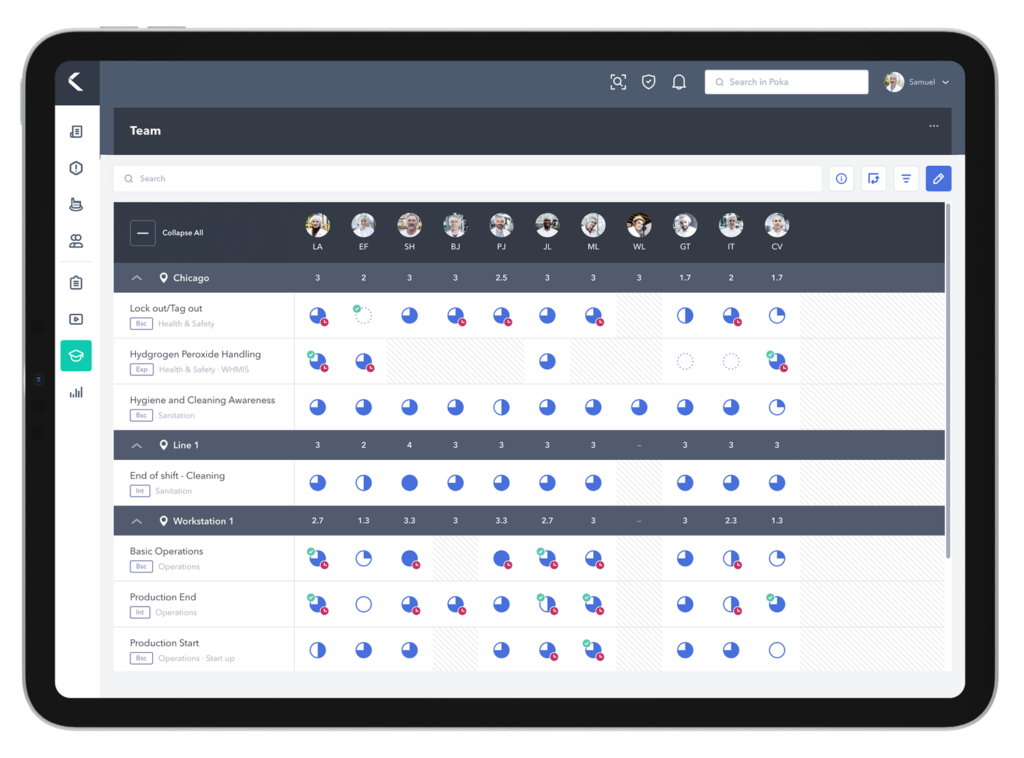

Poka provides tools (via mobile or tablet) for experienced operators to record real-world procedures, annotate steps, capture best practices, and share context (for instance, by video, photo, or textual tips). These recorded insights can then be incorporated into digital work instructions, checklists, or skills content. The system encourages collaboration and continuous improvement by involving frontline workers directly in the content-creation process.

Review and validation workflow: Once an operator or subject matter expert submits a procedure or tip, it can go through a review or approval step (by supervisors or technical leads) before being published.

Version control and editing: Poka supports versioning, so improvements or corrections can be tracked, and earlier versions retained.

Ongoing feedback loops: Other operators or users can provide comments or suggest refinements, which helps validate and refine the captured knowledge over time.

Tied to skills / training content: Captured tacit practices can be integrated into formal training or skills modules, where they then also benefit from assessments or endorsements.

By rolling out tacit knowledge capture, many users see:

Sustained productivity: fewer disruptions when experienced workers leave or rotate, since knowledge is retained and shared.

Accelerated content creation and iteration: because you engage experts in the frontline to contribute directly, your content evolves faster.

Reduced turnover effects: as newer or less experienced operators feel more supported (having access to best practices), retention improves.

A more competent and knowledgeable workforce: skill gaps shrink as captured insights are built into training and instructions.