Knowledge

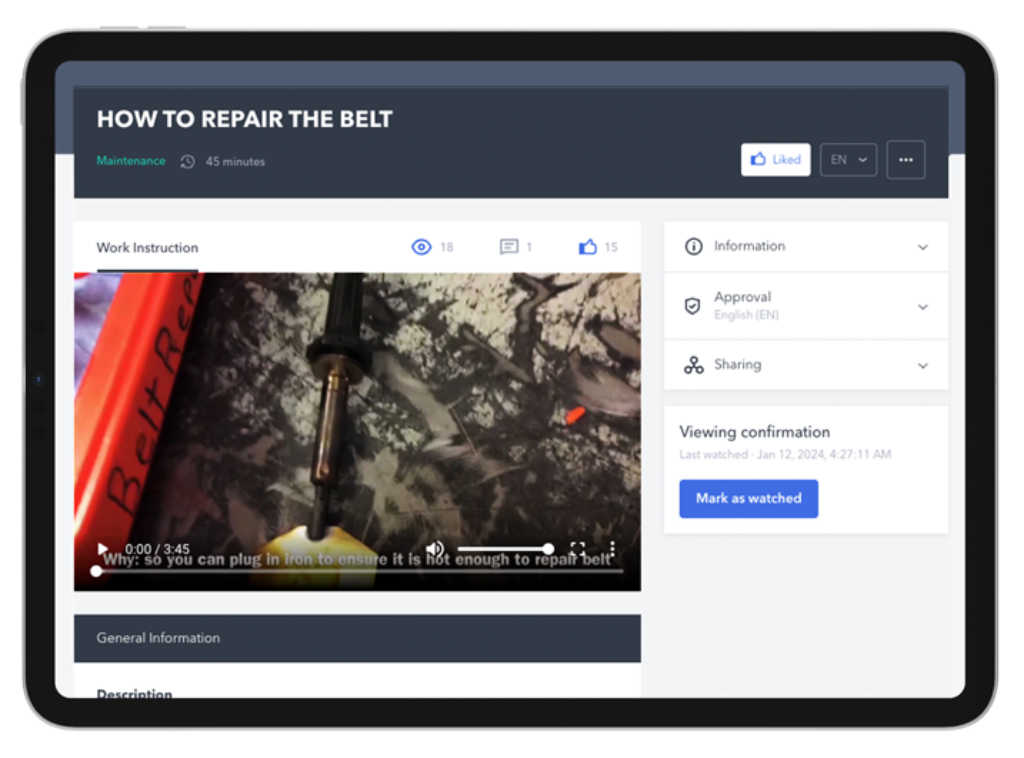

LOTO specific work instructions for each piece of machinery with added photos or videos clarify the precise steps to take during a LOTO ensuring compliance and completeness

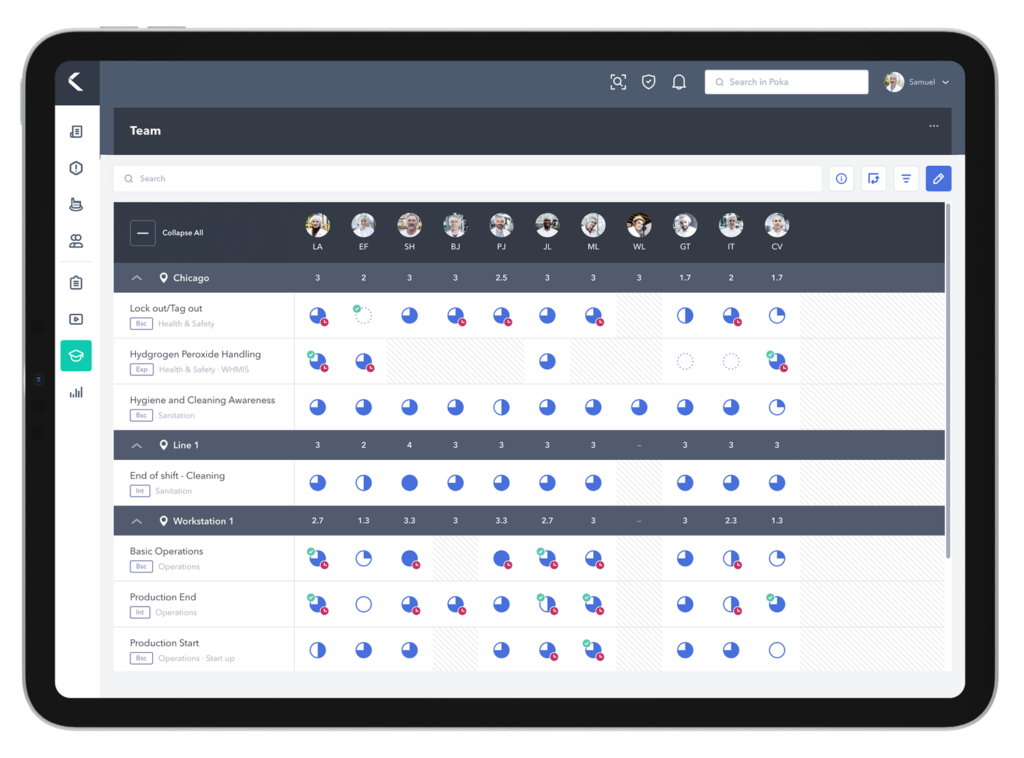

Viewing reports provide visibility to who has seen the work instructions for proper follow up