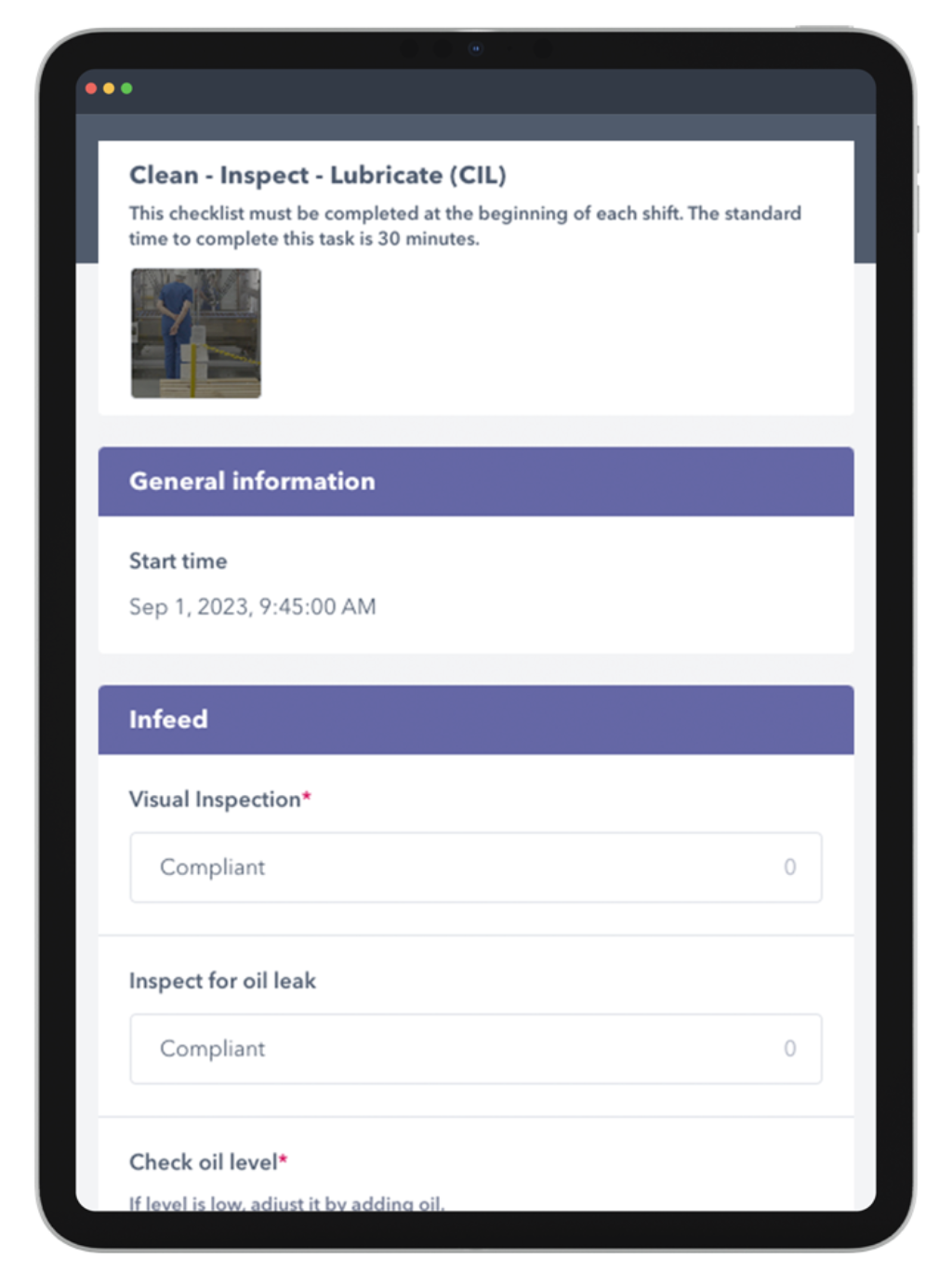

Forms & Checklists

- Digital Clean, Inspect, Lubricate (CIL) checklist can be created from a template

Clean, Inspect, Lubricate (CIL) schedules ensure AM tasks are completed

- Deviations are automatically flagged and notifications sent

Clean, Inspect, Lubricate (CIL) schedules ensure AM tasks are completed

Cleaning, inspection, and lubrication—often abbreviated as CIL—are routine maintenance tasks performed by operators to ensure equipment remains in optimal working condition. Cleaning removes contaminants, inspection identifies early signs of wear or failure, and lubrication reduces friction to extend equipment life.

In Total Productive Maintenance (TPM), CIL refers to Clean, Inspect, Lubricate activities carried out by operators as part of autonomous maintenance. It’s one of the foundational practices in TPM that helps prevent breakdowns, improve equipment reliability, and foster operator ownership of equipment care.

A CIL checklist is a standardized list of tasks that guides operators through the steps needed to properly clean, inspect, and lubricate equipment. It ensures consistency, improves accountability, and helps operators identify issues before they lead to equipment failure or production downtime.

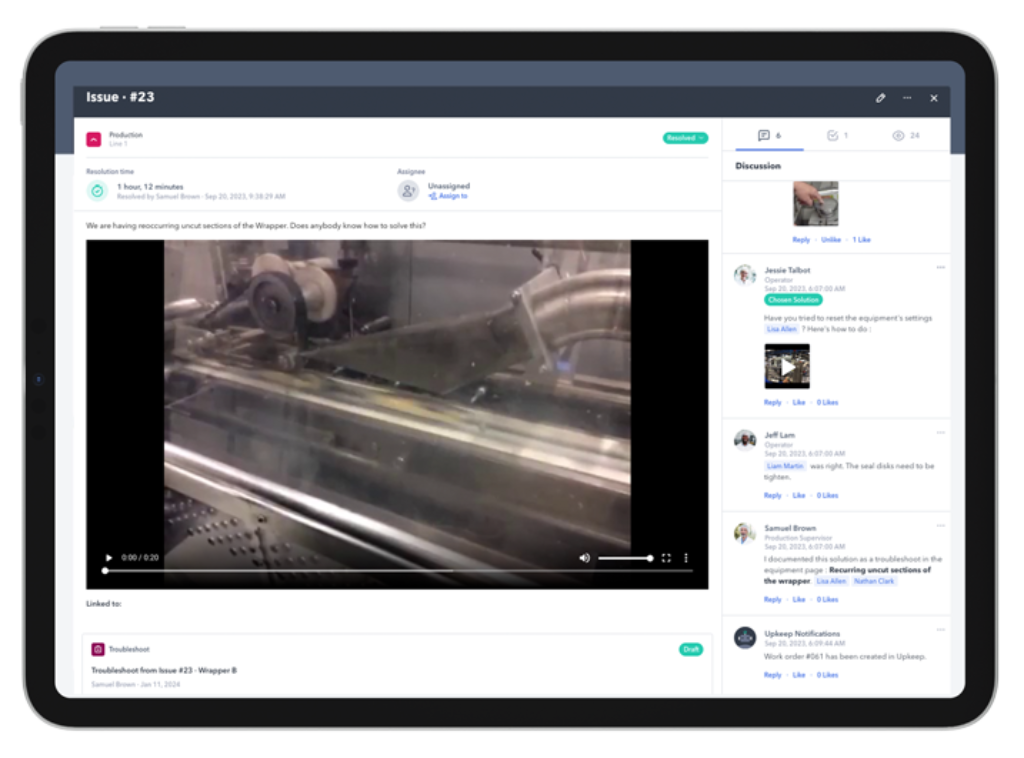

Digitizing CIL involves using a connected worker platform like Poka to replace paper checklists with mobile-friendly digital forms. Operators can follow guided steps, log findings, upload photos or videos of issues, and track completion in real time—making CIL tasks more efficient, auditable, and data-driven.