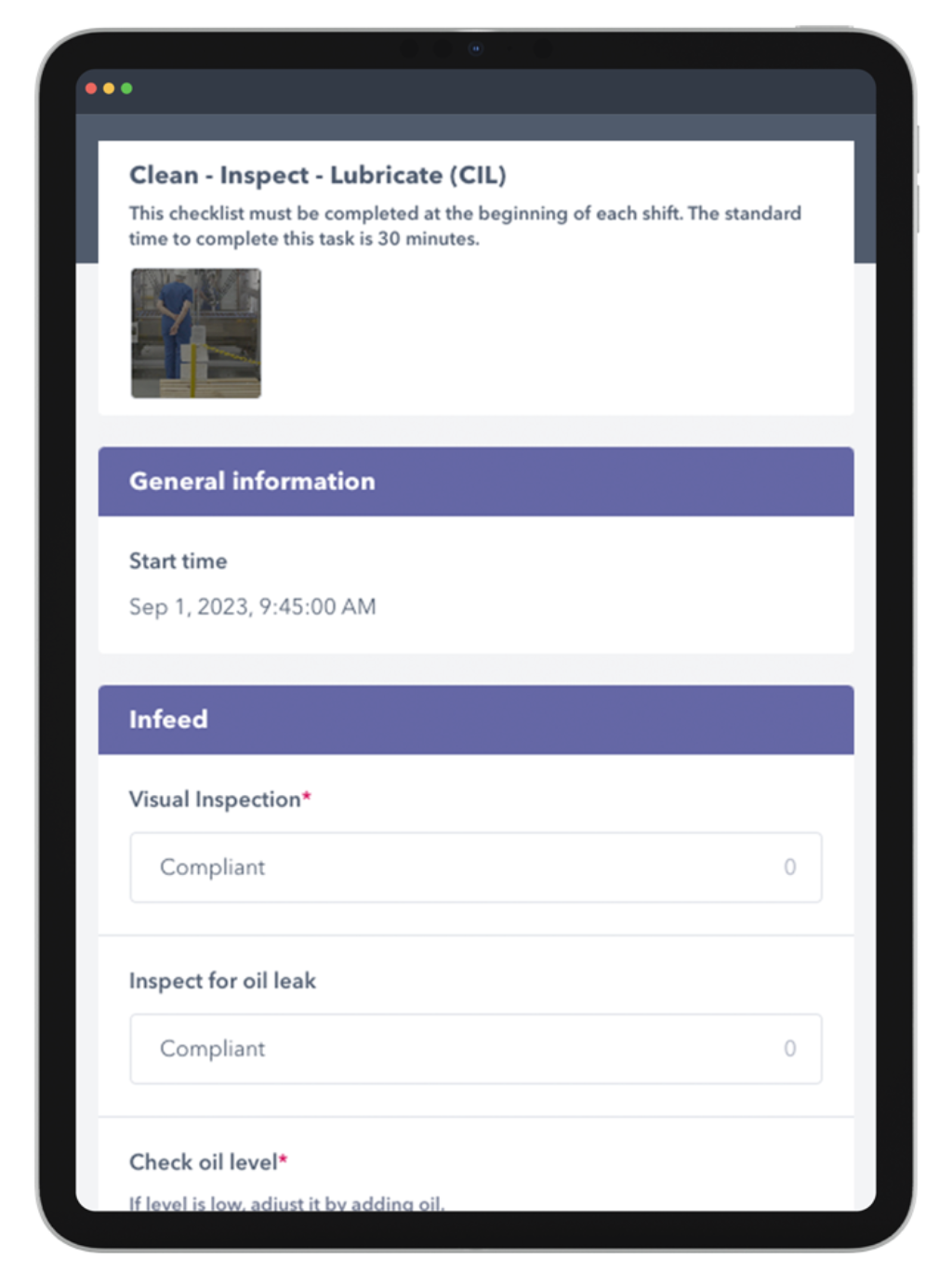

Forms & Checklists

- Digital checklists ensure product changeovers are being done properly and to standard

- Videos and photos of deviations during the changeover process facilitate problem solving

A product changeover is the process of switching a manufacturing line or equipment from producing one product to another. It involves a series of tasks such as cleaning, tool or part replacement, equipment calibration, and setup adjustments to meet the requirements of the next production run.

Product changeovers are essential for manufacturers that produce multiple SKUs or variants on the same line. They ensure that each product meets specific quality standards and regulatory requirements, while helping manufacturers stay flexible and responsive to customer demand.

Product changeover time refers to the total time required to transition from producing one product to the next. It includes all preparation, execution, and verification steps, and directly impacts equipment availability, production efficiency, and throughput. Reducing changeover time is key to minimizing downtime and increasing OEE.

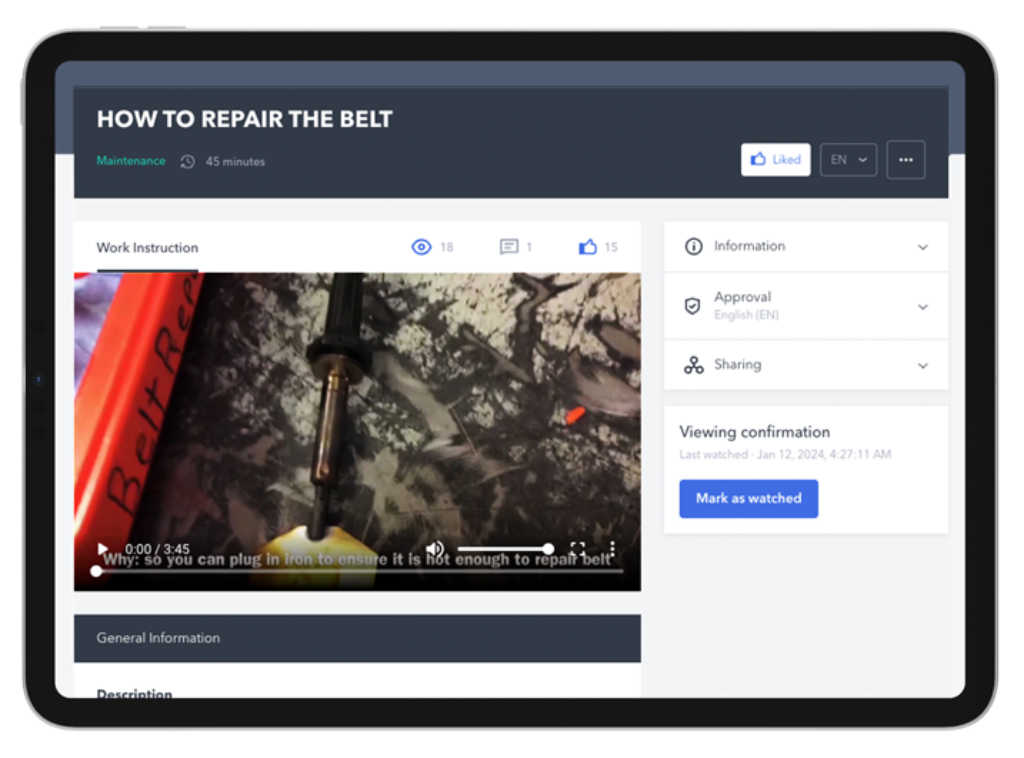

Digitizing a product changeover involves replacing paper-based checklists and instructions with digital tools. With a connected worker platform like Poka, teams can access step-by-step instructions, complete digital forms, record issues with photos or videos, and track completion in real time—all from a mobile device. This improves accuracy, speeds up execution, and enables continuous improvement through data analytics.