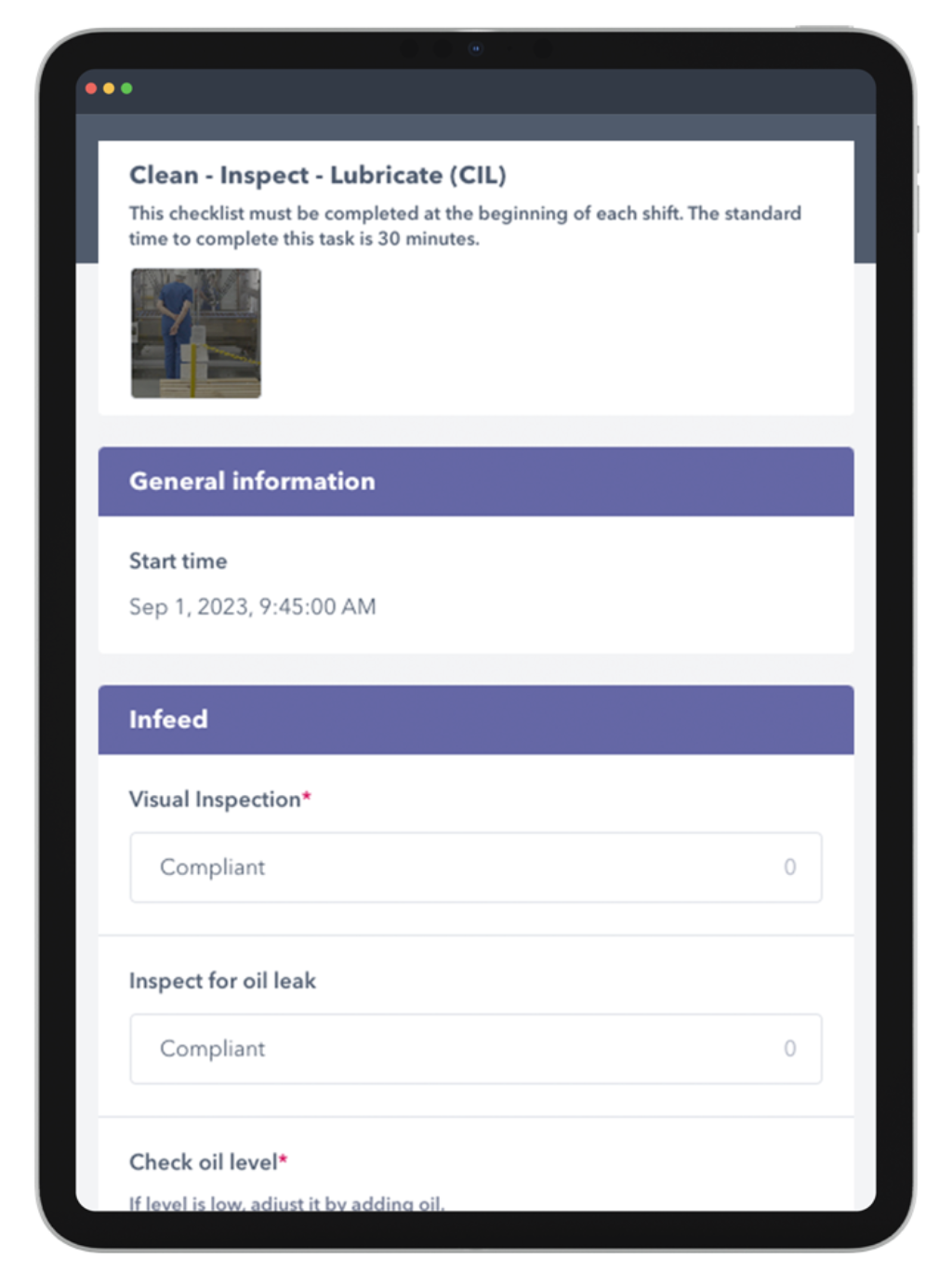

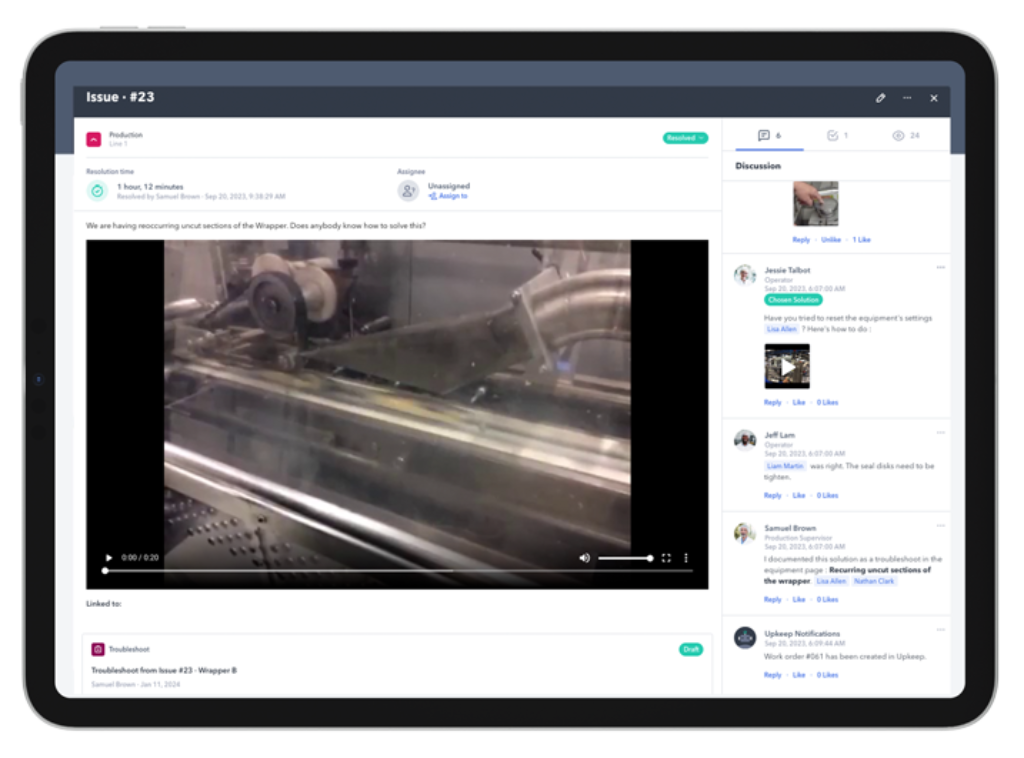

Forms & Checklists

Digital checklists are readily available to operators, ensuring that key steps are not skipped

Up to date checklists can be shared instantly within and across plants

- Scoring and scheduling provide visibility to completions and results